CHANGE-MAKERS, SPECIALISING IN PROCESS PLANTS FOR THE GREASE MANUFACTURING INDUSTRY

FLUID INNOVATION FOR A SUSTAINABLE FUTURE

At Ryland Research, we believe responsible innovation is about offering tailored solutions over one-size-fits-all approaches to empower industry leaders to innovate with confidence while keeping efficiency, sustainability, and quality at the core.

MORE EFFICIENT

PLANTS & EQUIPMENT

ENHANCED

FORMULATIONS

REDUCE ENERGY COSTS

AND CONSUMPTION

FUTURE-READY GREASE PLANTS

Designing a new plant or upgrading an existing one? We create tailored, efficient solutions that streamline production, minimise waste, and scale with your business—so you stay ahead in a changing industry.

BALANCING EFFICIENCY WITH SUSTAINABILITY?

Our waste heat recovery and fume management solutions help you cut costs, lower emissions, and meet regulatory standards—without compromising performance.

STRUGGLING WITH FORMULATION CONSISTENCY?

We provide expert review, refinement, and validation, ensuring your processes deliver maximum efficiency, quality, and reliability.

ENHANCING SAFETY, REDUCING RISK

Protecting your team starts with the right processes. We identify hazards, streamline operations, and recommend smart upgrades to improve workplace safety and compliance.

EXPERTISE BUILT OVER DECADES

For more than 30 years, we’ve helped companies around the world design and build equipment for manufacturing high-performance lubricating greases. We’re passionate about engineering smarter, more effective solutions, whether that means using cutting-edge technology or finding clever ways to do more with less.

We don’t just provide plant and machinery, we also help clients develop and refine grease formulations, from mono-soap and complex blends to non-melting types, for all kinds of uses.

From the blog

2-Stage vs 1 Stage Grease Manufacture

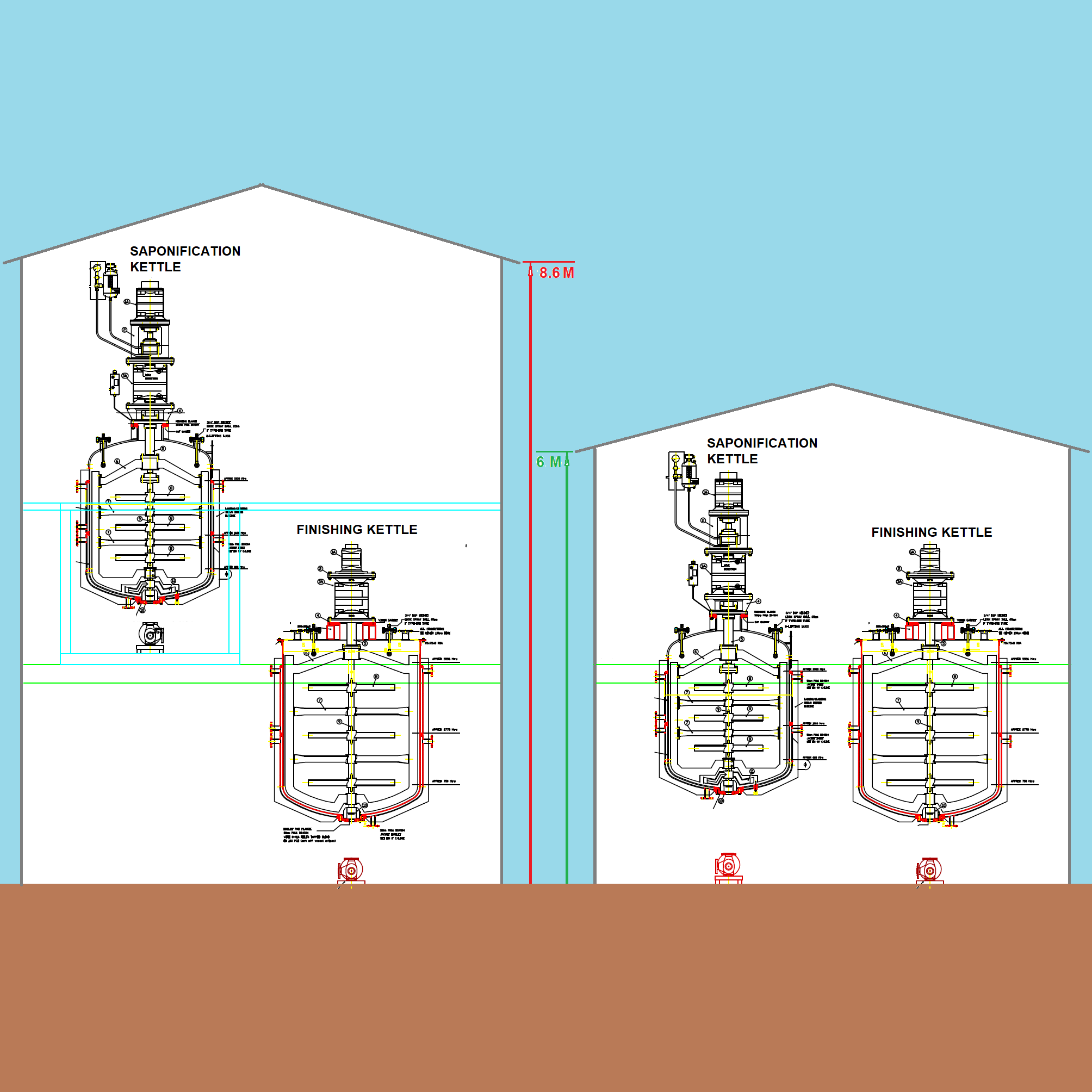

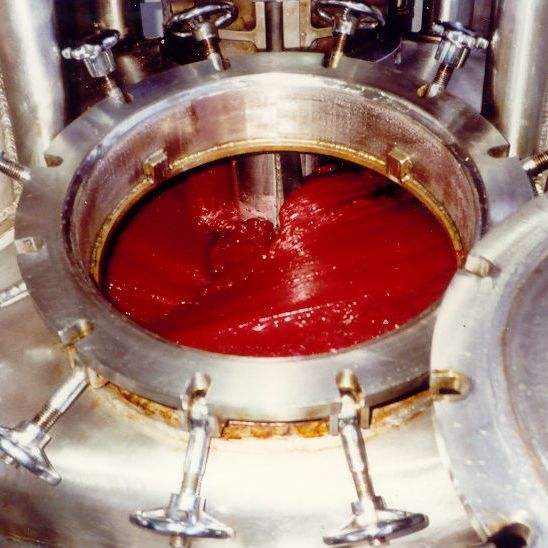

Small batches of grease are normally made in a single vessel. However, big batches are quite often made using a two-stage process where saponification (making the soap thickener in oil)

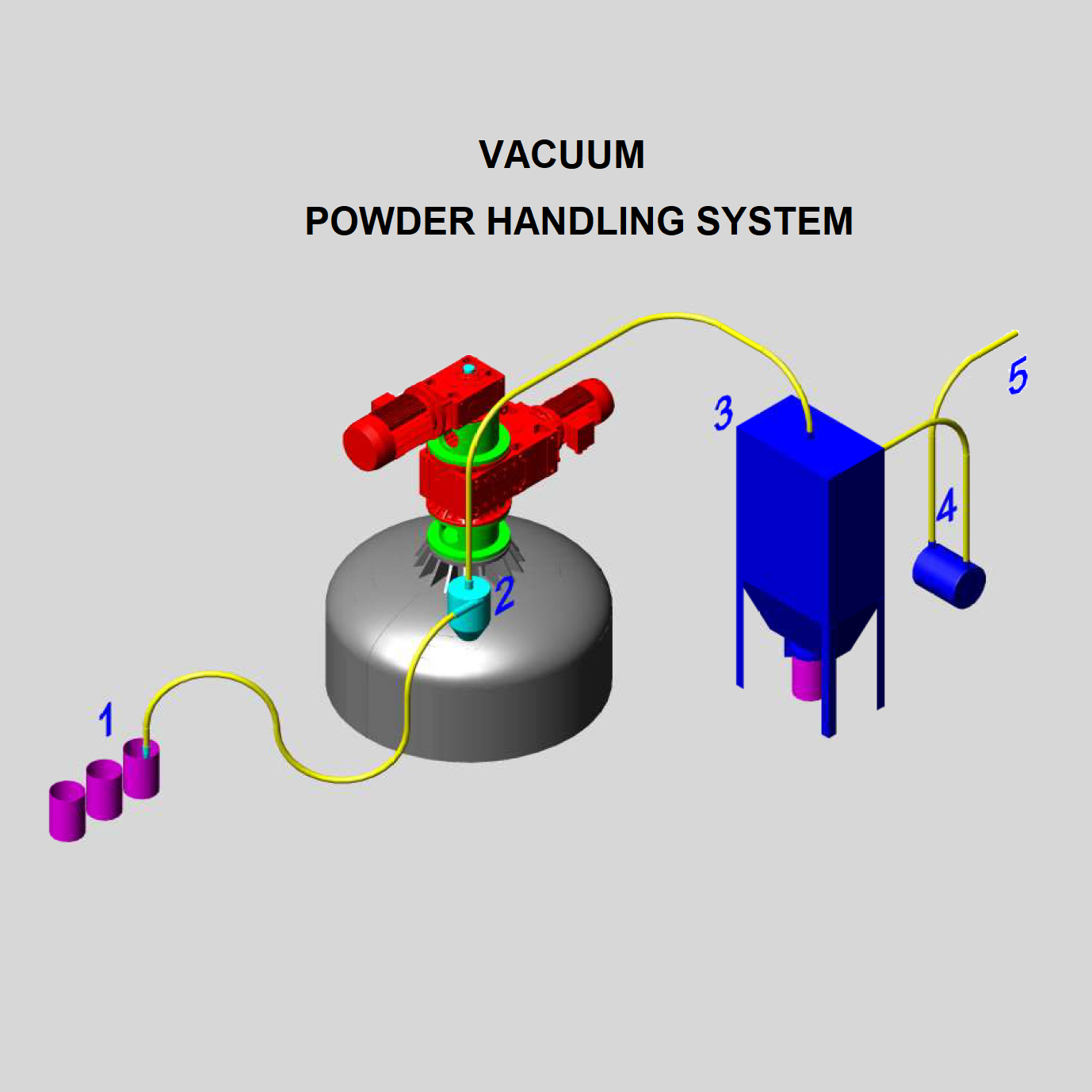

A Better Way to Put Powders into a Process Vessel

Surprisingly large and advanced manufactures in the chemical industry still physically empty bags of powders into process vessels via the manway. This can create a dust cloud that either contaminates

Fitting a Grease Plant into a Light Industrial Unit

One of the biggest problems with putting a grease plant into a light industrial unit is the amount of headroom available. Historically, run major companies fitted grease manufacturing plants in

Which Grease Should You Manufacture First?

Contrary to intuition, you need simpler and thus cheaper equipment to manufacture the more expensive complex greases, than cheaper mono-soap greases. Calcium grease, the cheapest type, foams badly during saponification