Powder Transfer by Vacuum

It’s surprising how many advanced manufacturers in the process industry still empty bags or kegs of powder directly into process vessels through the manway.

This approach often creates a dust cloud that contaminates the factory or gets drawn into the vessel’s fume extraction system — coating internal surfaces and clogging filters. The problem is even worse in heated vessels, where vapours can mix with the powder to form a stubborn layer or “cake.”

Are you still loading powders this way? We offer a cleaner, safer, and far more efficient alternative.

How It Works

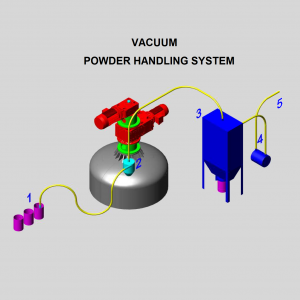

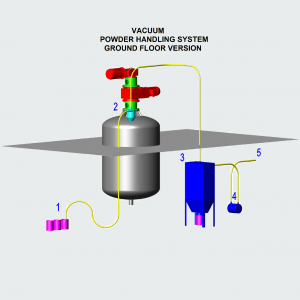

The powder handling system operates as an efficient, enclosed method for transferring powders safely into process vessels.

The system includes:

- Suction hose: The operator dips this into the powder container, drawing the material up in the same way as using a domestic vacuum cleaner.

- Mancunian head: Separates powder from air using a cyclone. The powder drops into the vessel, while the air exits through a centrally mounted port.

- Reverse jet filter: Captures and recovers the small percentage of powder that passes through the initial separation stage.

- Vacuum pump: Generates the suction required to move the powder.

- Exhaust: Safely vents filtered air outside the building.

As shown in the system diagram.

PROVEN PERFORMANCE since the 1970’s

In the 1970s, Jet-Lube Lubricants Ltd in Maidenhead, UK, expanded its production of oilfield thread compounds — blends of grease and metal powders designed to prevent metal-to-metal contact between drill pipes, rods, casing and tubing.

The powders used at the time included copper, zinc and lead, which raised health and safety concerns around airborne dust exposure. To address this, Tom Ryland, then Managing Director, introduced the vacuum handling system to all oilfield compound mixers.

This innovation significantly reduced airborne contamination, and lead was later removed from the formulations entirely in the 1990s for environmental reasons.

The system operated successfully for more than thirty years, with annual blood tests consistently showing safe lead levels. The only major upgrade during that time was the replacement of the manually shaken filter with an automatic reverse-jet unit, further improving efficiency and safety.

Do I need a vacuum rated process vessel?

Not necessarily. While your process vessel may operate under a slight negative pressure, the vacuum level is typically very low.

However, if your system uses D-Lid access manways (like the one on the finishing kettle shown on the right), you should fit draught-excluder style foam seals around the lid edges to minimise air leakage. The piano hinge will still allow a small amount of airflow, but not enough to affect system performance.