CHANGE-MAKERS IN

PROCESS PLANT ENGINEERING FOR THE GREASE INDUSTRY

FLUID INNOVATION FOR A SUSTAINABLE FUTURE

At Ryland Research, we believe responsible innovation means creating tailored solutions — not one-size-fits-all approaches. We help industry leaders innovate with confidence by keeping efficiency, sustainability, and quality at the heart of everything we do.

MORE EFFICIENT

PLANTS & EQUIPMENT

ENHANCED

FORMULATIONS

REDUCE ENERGY COSTS

AND CONSUMPTION

FUTURE-READY GREASE PLANTS

Designing a new plant or upgrading an existing one? We build tailored, efficient solutions that streamline production, reduce waste, and grow with your business. Helping you to stay ahead in a changing industry.

BALANCING EFFICIENCY WITH SUSTAINABILITY?

Looking to improve efficiency while reducing environmental impact? Our waste heat recovery and fume management systems help you cut costs, lower emissions and stay compliant without compromising performance.

IMPROVING FORMULATION CONSISTENCY?

Inconsistent results slowing production? We review, refine and validate your processes to deliver greater efficiency, quality and reliability every time.

ENHANCING SAFETY, REDUCING RISK

Protecting your people starts with the right processes. We help identify hazards, streamline operations and recommend smart upgrades that strengthen safety and compliance across your plant.

EXPERTISE BUILT OVER DECADES

For more than 30 years, we’ve helped companies worldwide design and build equipment for manufacturing high-performance lubricating greases. Our passion is engineering smarter, more effective solutions, whether that means applying the latest technology or finding innovative ways to do more with less.

Beyond plant and machinery, we also support clients in developing and refining grease formulations, from mono-soap and complex blends to non-melting types, tailored for a wide range of uses.

From the blog

Anchor scraper selection – No single correct answer

In common with Industry practice, we fit wall and floor scrapers to the agitation on our Grease Kettles. Scrapers peel the product off the vessel wall and floor to stop

Is there a right and wrong way to de-aerate grease?

There is no right or wrong way to de-aerate grease. In the perfect manufacturing process, there would be no air in the grease needing removal. In reality, the agitation and

Load Cell Mounting Process Vessels

You may be tempted to assume that load cell mounting process vessels always makes raw material additions more reliable. However, you need to consider the following: Mass of the process

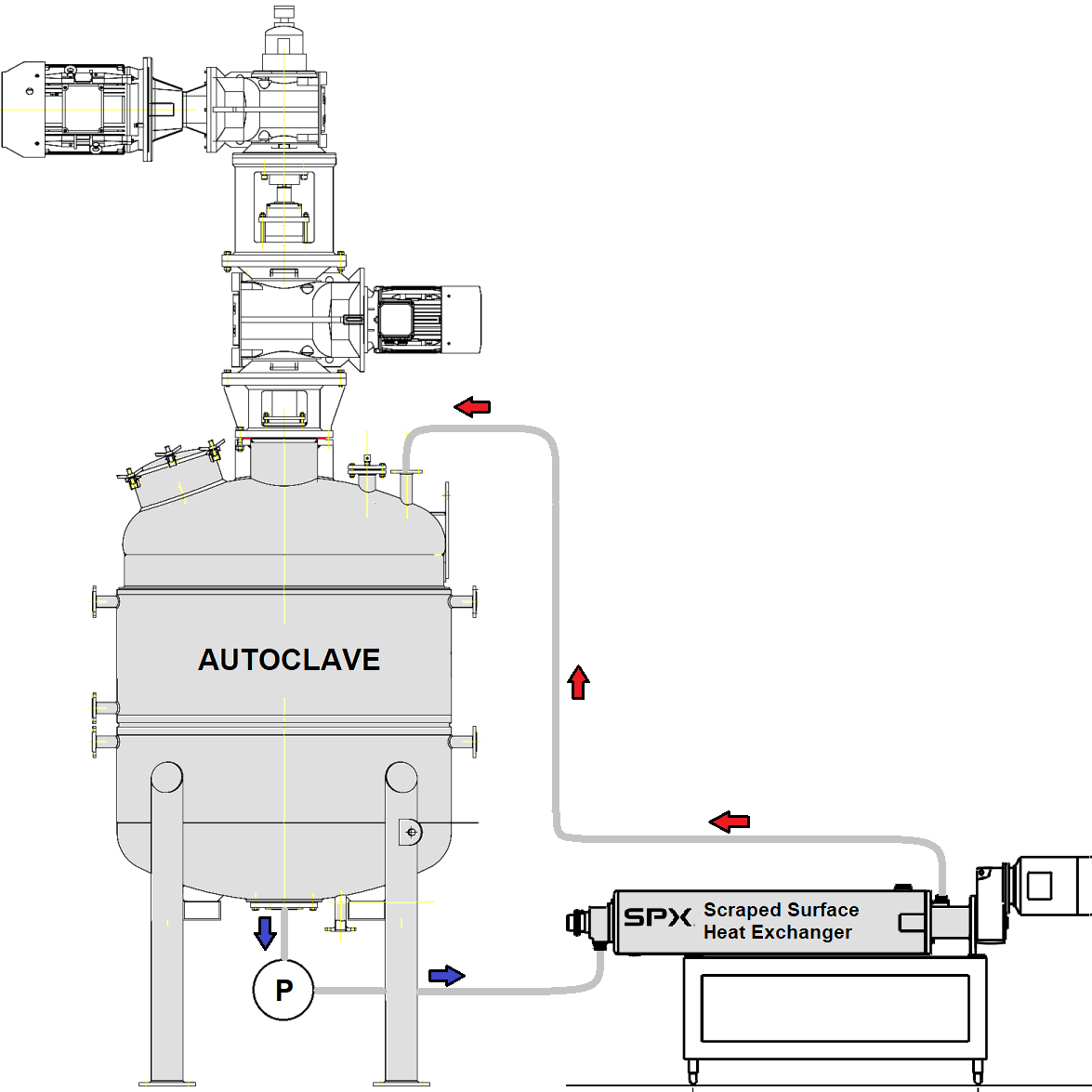

Could a Scraped Surface Heat Exchanger Speed Up Grease Manufacture?

Large grease batches usually take longer to make than small grease batches. This is because the vessel’s jacket area does not increase in proportion to the mass of the contents.