Process Vessels

Process vessels are at the heart of our grease plant projects. For smaller plants, we typically use a single-stage process, with a kettle handling both saponification and finishing. Larger plants usually require a two-stage process: first saponification in an autoclave or kettle, then finishing in vessels where base oils and additives are introduced.

All our process vessels are built by trusted UK manufacturing partners to our designs. Where projects demand, we can also source internationally — provided quality and reliability meet our standards.

Saponification

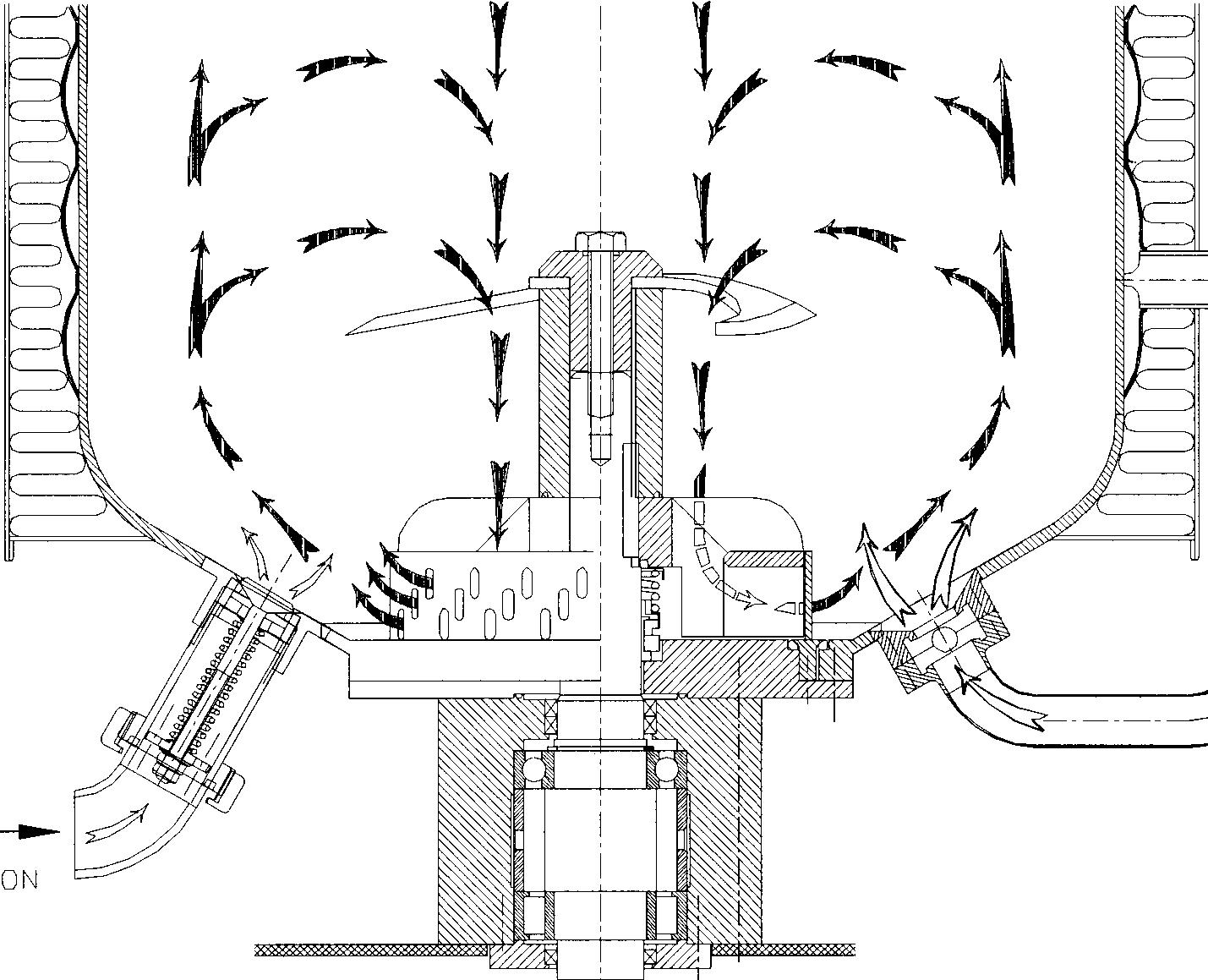

This is a contra-rotating, jacketed vessel designed specifically for saponification and complexing reactions.

Key features:

- Contra-rotating design with high-powered inner paddle agitation to accelerate reaction rates and ensure complete mixing

- Pressurised build option that enhances mono-soap formation

- Jacket zoning available for efficient half-batch operation

- Variable-speed inverter drives to reduce agitation speed for shear-sensitive products

If required, we can also source grease contactors with internal jackets to improve heating rates. This approach can be beneficial for high-volume manufacture of a limited number of grease types. However, the internal jacket’s annular space may become blocked when producing high drop point greases.

Finishing

Finishing is the next stage after saponification or complexing. The finishing kettle is a jacketed, contra-rotating vessel designed for precise temperature and agitation control.

Features include:

- Slow-speed outer gate and high-speed incorporator for effective mixing

- Variable-speed drives for process flexibility

- Optional double-zone jacket for smaller batch sizes

If required, our finishing kettles can also handle the entire grease-making process, from saponification or complexing through to finishing.

Bottom End Dispersion and Turbo Mixing

A bottom-mounted dispersion unit can significantly improve complex grease production by preventing the build-up of partially reacted soap at the base of the vessel.

We have supplied several configurations to achieve this:

- Turbo mixer with a high-power bottom-entry turbine and gate

- Contra-rotating system with an additional lower blade for enhanced mixing

- Triple-motion system combining a low-speed gate or anchor, a medium-speed inner agitator, and a high-speed bottom agitator

We also offer turbo mixers for high-speed dispersion of solids into grease and for gelling oils or fluids with thickeners such as silica. The higher dispersion speed increases throughput, allowing more batches to be completed each day.