CHUTNEY MAKER INTO COMPLEX GREASE TURBOMIXER

A client approached us to develop equipment for manufacturing complex greases. Although a standard grease kettle can handle most formulations, a high-shear or turbomixing vessel can deliver superior results.

Purpose-built turbomixing kettles can be expensive, so we sourced a pilot-scale Scanima Turbomixer, originally used for making chutneys and sauces, and successfully repurposed it for grease production.

We adapted the unit by:

- Converting the steam heating system to thermal oil for higher temperature capability without high pressure

- Adding a supplementary heating jacket underneath the vessel

- Sealing unused bottom inlets

- Rebuilding the discharge valve to handle higher temperatures

- Replacing the lid seal with one rated for increased temperature tolerance

- Extending the scraper to clean both the sides and the vessel floor

- Integrating a heat transfer oil thermoregulator, product transfer pump and Charlotte mill

The repurposed mixer was used to produce calcium sulphonate complex and lithium complex greases. It was later purchased by a major UK grease manufacturer for small-scale and pilot production.

COST-EFFECTIVE ALCOHOL HAND SANITISER MIXER

Our challenge was to create a small-scale hand sanitiser blender with minimal investment. The aim was not to cut corners, but to reduce financial risk in a commercially uncertain market.

Even with a lean design, we maintained the highest standards of safety and build quality, including:

- Stainless steel and inert plastic contact surfaces

- ATEX-rated drive to manage explosion risk

- High-shear mixing capability to achieve proper thickening

Main components:

- 120-litre poly drum

- Two-pole ATEX-rated drive motor

- Variable-speed inverter drive

- Jet-ski impeller

Fabrication is currently ongoing, with final testing and validation to follow.

CONVERTING A TORNADO GAS TURBINE INTO A HOVERCRAFT ENGINE

Traditionally, two-stroke engines have provided the best power-to-weight ratio for portable and lightweight applications such as hovercraft. However, tightening emissions regulations are making them increasingly difficult to source.

We identified a creative alternative: components from Tornado fighter aircraft, specifically the T312 Auxiliary Power Unit (APU), now available on the used market at reasonable cost.

ADVANTAGES

- Manufactured by Rolls Royce and BMW, the T312 APU delivers over 140 BHP while weighing only 40 kg

- Exceptional power-to-weight ratio

- Built-in compressor air vent capable of producing a high volume of compressed air for ancillary systems

DISADVANTAGES

- Fixed output speed of 8,000–8,560 RPM, which requires a variable pitch fan or continuously variable transmission

- Efficiency decreases and exhaust temperature rises if the turbine speed is reduced, increasing fuel consumption and potentially shortening turbine life

- The APU is flange-mounted at the drive end with a non-standard mounting configuration

- It also has a splined socket instead of a conventional output shaft, which limits compatibility with standard couplings

SOLUTIONS

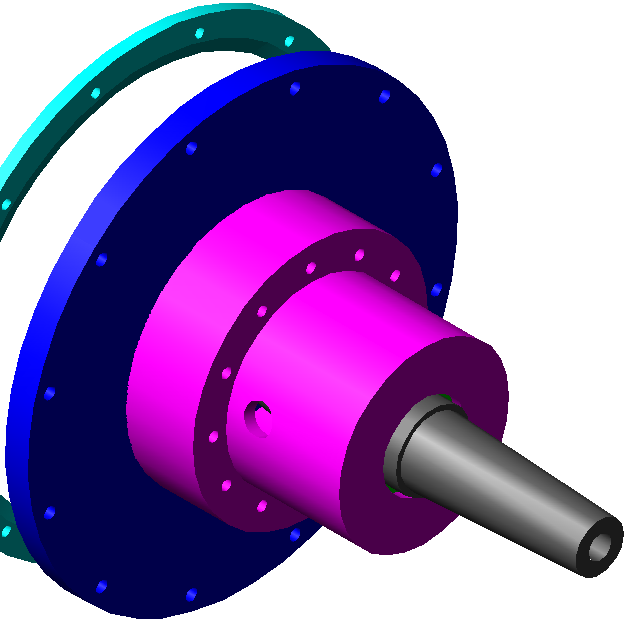

To overcome these challenges, we designed and machined a custom adapter shaft that is splined at one end and tapered at the other, allowing connection to a timing pulley that drives a belt-linked hovercraft fan.

We have completed the bearing housing design and are now developing a support frame that will allow the turbine to be securely foot-mounted in the hovercraft.

POTENTIAL APPLICATIONS

Beyond hovercraft propulsion, the APU system could also be used for:

- Field water pumping

- Portable power generation

- Combined heat and power systems

- Light aircraft or small airship propulsion