Blog

Our blog shares thought-provoking articles on engineering insights, industry challenges, and practical ideas from our work in process plant design and beyond. We aim to spark discussion and provide useful perspectives — and if there’s a topic you’d like us to explore, we’d love to hear from you.

Anchor scraper selection – No single correct answer

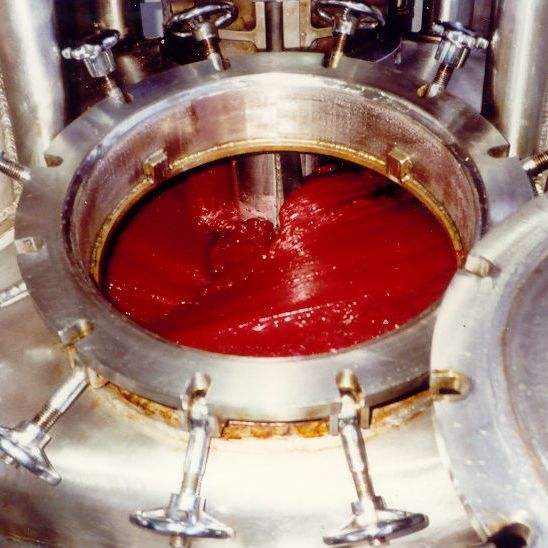

In common with Industry practice, we fit wall and floor scrapers to the agitation on our Grease Kettles. Scrapers peel the product off the vessel wall and floor to stop

Is there a right and wrong way to de-aerate grease?

There is no right or wrong way to de-aerate grease. In the perfect manufacturing process, there would be no air in the grease needing removal. In reality, the agitation and

Load Cell Mounting Process Vessels

You may be tempted to assume that load cell mounting process vessels always makes raw material additions more reliable. However, you need to consider the following: Mass of the process

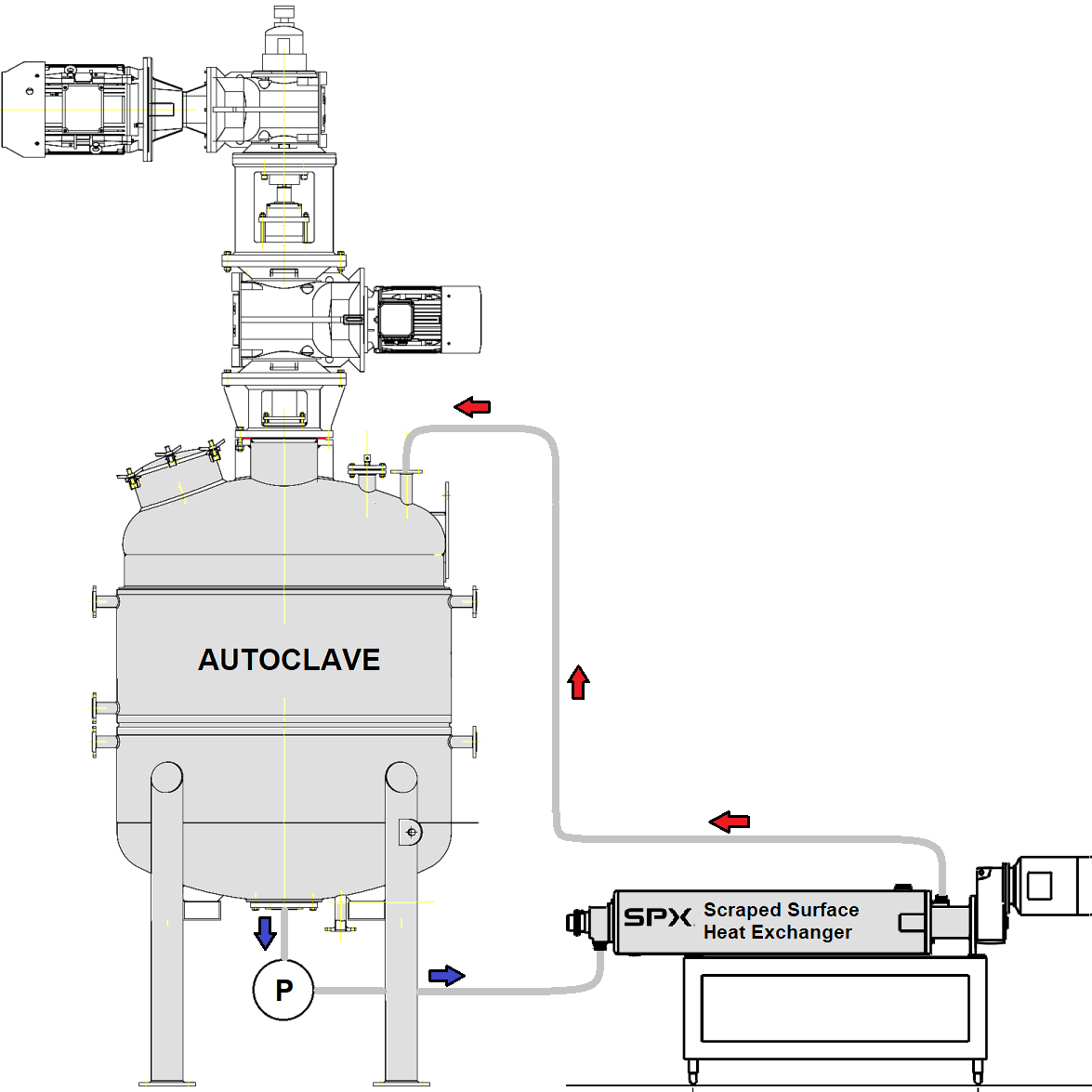

Could a Scraped Surface Heat Exchanger Speed Up Grease Manufacture?

Large grease batches usually take longer to make than small grease batches. This is because the vessel’s jacket area does not increase in proportion to the mass of the contents.

2-Stage vs 1 Stage Grease Manufacture

Small batches of grease are normally made in a single vessel. However, big batches are quite often made using a two-stage process where saponification (making the soap thickener in oil)

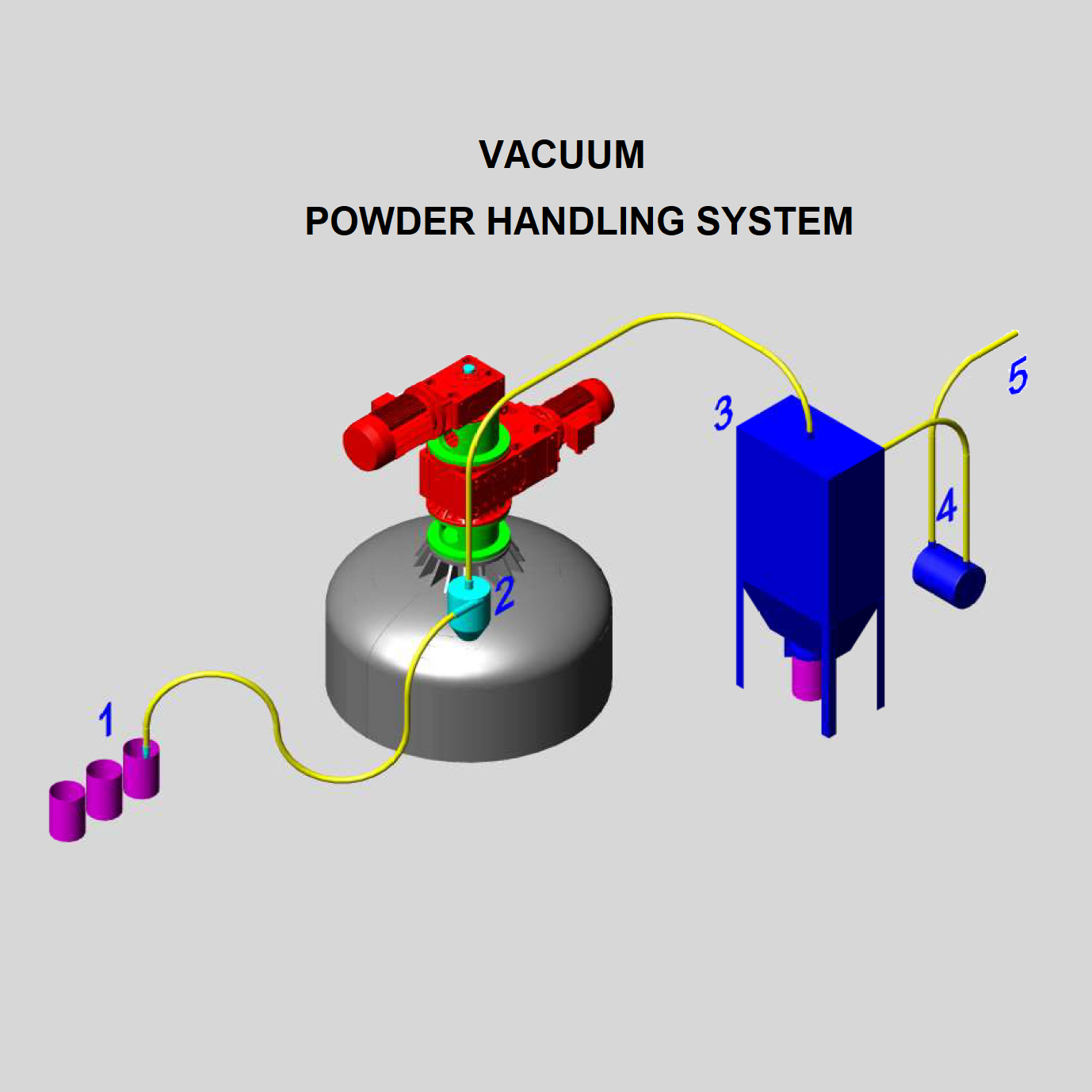

A Better Way to Put Powders into a Process Vessel

Surprisingly large and advanced manufactures in the chemical industry still physically empty bags of powders into process vessels via the manway. This can create a dust cloud that either contaminates

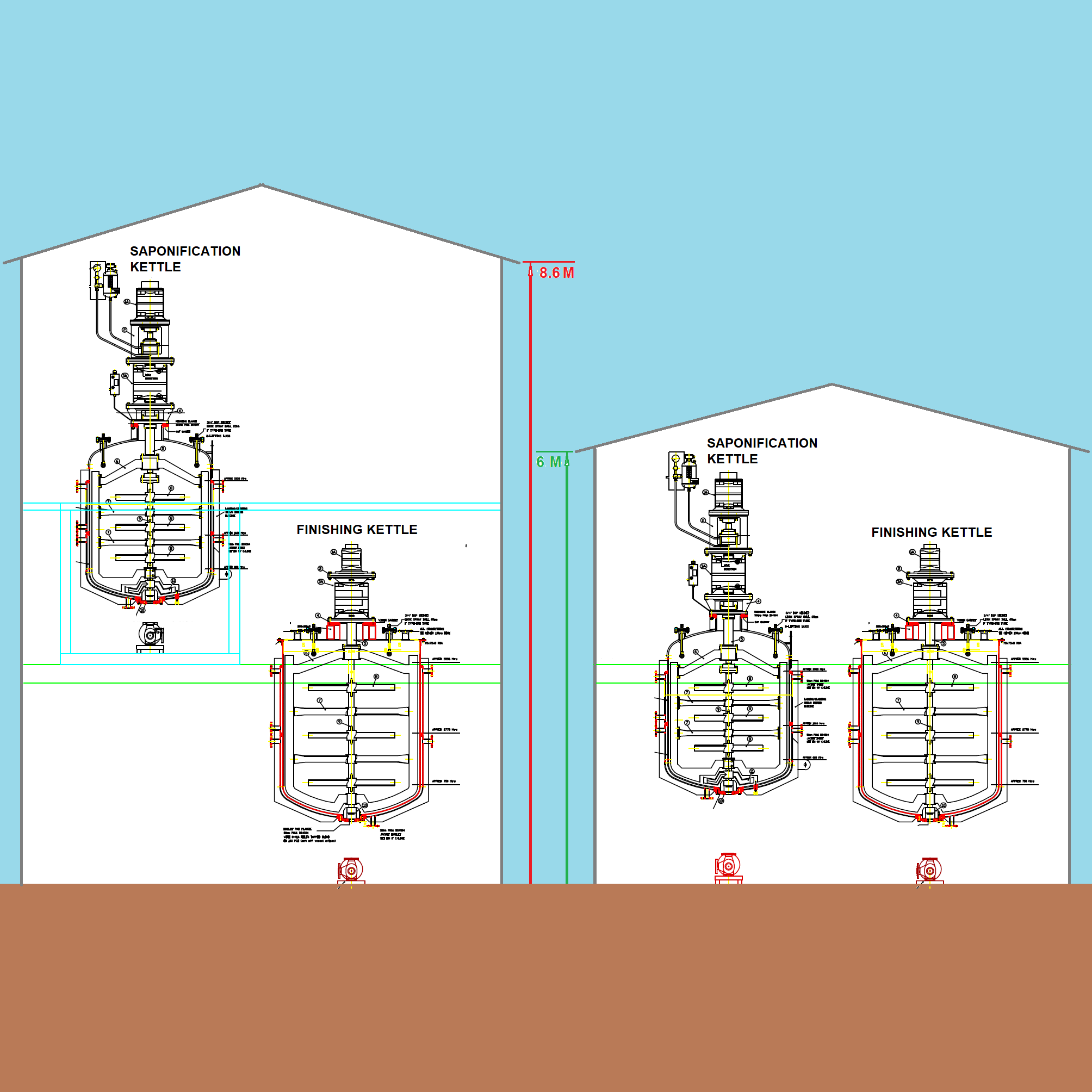

Fitting a Grease Plant into a Light Industrial Unit

One of the biggest problems with putting a grease plant into a light industrial unit is the amount of headroom available. Historically, run major companies fitted grease manufacturing plants in

Which Grease Should You Manufacture First?

Contrary to intuition, you need simpler and thus cheaper equipment to manufacture the more expensive complex greases, than cheaper mono-soap greases. Calcium grease, the cheapest type, foams badly during saponification

Process Upgrading or Changing – Can it Cause Unexpected Changes to the Product?

Sometimes it is necessary to change processes to improve productivity. However, there is a concern that the finished product may look different to the customer, even if the performance is

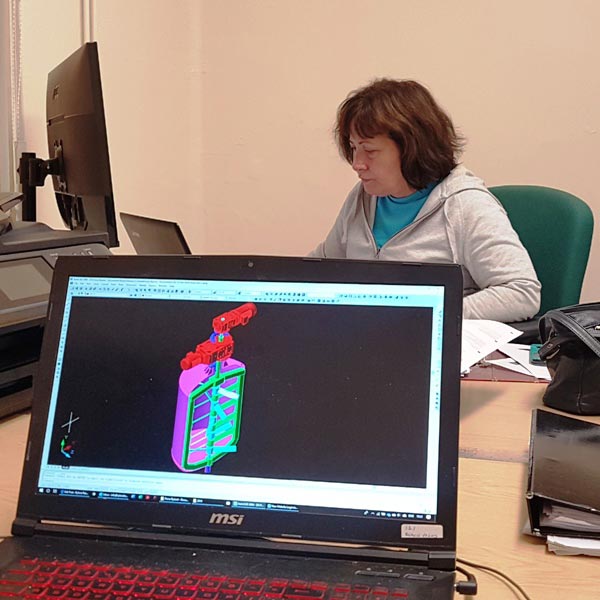

Automating process plants – common mistakes and how to avoid them

The Fears “Can we use this?”, asked the client when pointing to the two grease kettles during a recent commissioning visit, “without using this?”, when pointing to the two control

What can possibly go wrong?

You can anticipate most technical and financial problems that could arise in an engineering project, but there can also be the totally unexpected ones that trip you up later. Here

Commissioning visits – what we have learnt

If we were asked; “What is a typical commissioning visit like?”, we would be tempted to reply; “There is no such thing as a typical commissioning visit”. Although there are

Change of service

They say “You Live and Learn” and for us what we have learnt in recent years of managing grease manufacturing plant projects, is that the client’s major issue is often